The Starrett Drill Chart PDF is a comprehensive guide providing drill sizes, decimal equivalents, and tap sizes for both metric and imperial systems. It is widely used in machining, manufacturing, and engineering to ensure precision and accuracy. The chart is essential for professionals and hobbyists alike, offering a quick reference for selecting the correct drill and tap sizes. Available for free download, it is a valuable resource for anyone working with metal or plastic materials, ensuring efficient and precise drilling operations across various industries.

Overview of the Starrett Drill Chart

The Starrett Drill Chart is a detailed reference guide that lists drill sizes, decimal equivalents, and corresponding tap sizes for both metric and imperial measurements. It provides a comprehensive table that helps users match drill sizes to tap sizes accurately, ensuring precision in machining and manufacturing processes. The chart includes a wide range of sizes, from small to large, and is designed to be user-friendly for professionals and hobbyists alike. Its clarity and organization make it an essential tool for achieving accurate and efficient drilling operations.

Importance of Drill and Tap Charts in Machining

Drill and tap charts are essential tools in machining, ensuring precision and accuracy when creating threaded holes. They provide clear mappings of drill sizes to tap sizes, preventing errors in thread creation. By referencing these charts, machinists can avoid costly mistakes, such as incorrect tap sizes or drill diameters. This saves time and materials, making the manufacturing process more efficient. The Starrett Drill Chart, in particular, is widely recognized for its reliability and comprehensiveness, making it a critical resource for professionals and hobbyists alike in achieving precise and professional results.

History and Development of Starrett Drill Charts

The Starrett Drill Chart traces its origins to the L.S. Starrett Company, founded in 1880, specializing in precision tools. Over time, the chart evolved to include both metric and imperial standards, becoming an indispensable resource for machinists. Its accuracy and comprehensive design solidified Starrett’s reputation as a leader in toolmaking, with continuous updates reflecting advancements in manufacturing technology.

The Evolution of Starrett as a Leading Toolmaker

Founded in 1880, the L.S. Starrett Company has grown into a global leader in precision tools and measurement instruments. Known for innovation and quality, Starrett introduced the drill chart to meet the growing needs of machining and manufacturing. Over the years, the company expanded its product line, incorporating metric and imperial standards to cater to a diverse clientele. Today, Starrett’s drill charts are industry benchmarks, trusted by professionals and hobbyists alike for their accuracy and reliability in various applications, from aerospace to DIY projects.

How Starrett Drill Charts Have Become an Industry Standard

Starrett drill charts have become the industry standard due to their precision, reliability, and comprehensive coverage of drill and tap sizes. Widely used in machining, manufacturing, and engineering, they provide quick references for selecting the right tools. Their availability in PDF format has made them easily accessible for professionals and hobbyists. The charts’ accuracy and versatility in covering both metric and imperial systems have solidified their reputation as essential resources, trusted across industries for ensuring precise and efficient drilling operations.

Understanding Drill Sizes and Decimal Equivalents

The Starrett Drill Chart provides a detailed table of drill sizes in fractions and decimal equivalents, along with corresponding tap sizes for both metric and imperial systems. This resource ensures accurate conversions and precise matching of drill bits to tap sizes, making it an indispensable tool for machinists, engineers, and manufacturers. Its clarity and comprehensiveness have made it a trusted reference across industries.

How to Interpret Drill Sizes in the Starrett Chart

The Starrett Drill Chart lists drill sizes in fractions of an inch, decimals, and corresponding tap sizes for both imperial and metric systems. Each drill size is paired with its decimal equivalent, making it easy to convert between fractional and decimal measurements. For example, a #80 drill bit corresponds to 0.0135 inches. The chart also provides tap sizes for various thread pitches, allowing users to match the correct drill size to their specific threading needs. This straightforward organization helps professionals and hobbyists quickly identify the right drill size for their projects, ensuring precision and efficiency in machining operations. The chart’s clarity and detailed information make it an essential tool for accurate drill and tap size selection across industries.

Conversion of Drill Sizes to Decimal Equivalents

The Starrett Drill Chart provides a straightforward method for converting drill sizes to their decimal equivalents. Drill sizes are listed in fractions of an inch, such as 1/64 or 1/32 increments, and are directly paired with their decimal measurements. For example, a #80 drill corresponds to 0.0135 inches, while a #64 drill is 0.0156 inches. This conversion system allows users to quickly identify the exact decimal size for any drill bit, ensuring precision in machining and manufacturing processes. The chart’s organized layout makes it easy to find the decimal equivalent for any drill size, eliminating guesswork and reducing errors in drill selection.

Metric vs. Imperial Tap Sizes

The Starrett Drill Chart PDF distinguishes between metric and imperial tap sizes, providing precise measurements for global compatibility. Metric taps are based on millimeter standards, while imperial taps use inch-based measurements, ensuring versatility across international projects and applications.

Differences Between Metric and Imperial Tap Sizes

Metric tap sizes are measured in millimeters, while imperial taps use inches. Metric taps follow ISO standards, with sizes like M3, M4, and M5, while imperial taps use fractional or decimal measurements. Thread pitch differs too, with metric taps measured in threads per millimeter and imperial taps in threads per inch. These differences affect compatibility and application, requiring careful conversion to ensure accuracy. The Starrett Drill Chart PDF provides clear distinctions and conversions, aiding users in selecting the correct tap size for their specific needs, whether working in metric or imperial systems.

How to Choose the Right Tap Size for Your Drill

To choose the right tap size for your drill, refer to the Starrett Drill Chart PDF, which provides a quick reference guide for both inch and metric systems. Match the drill size to the corresponding tap size for the desired thread type (e.g., coarse or fine). Ensure the thread pitch and major diameter align with your project requirements. The chart also includes decimal equivalents and pipe thread sizes, making it easier to select the correct tap size for precise and accurate results in machining and manufacturing applications.

How to Read the Starrett Drill Chart

The Starrett Drill Chart is a quick reference guide for matching drill sizes to tap sizes. It lists drill sizes in decimal or fractional formats, along with their corresponding tap sizes for both inch and metric systems. Users can easily find the appropriate drill size for a specific tap size by aligning the decimal equivalent or fractional measurement with the desired thread type. This ensures accurate and efficient selection of tools for machining applications.

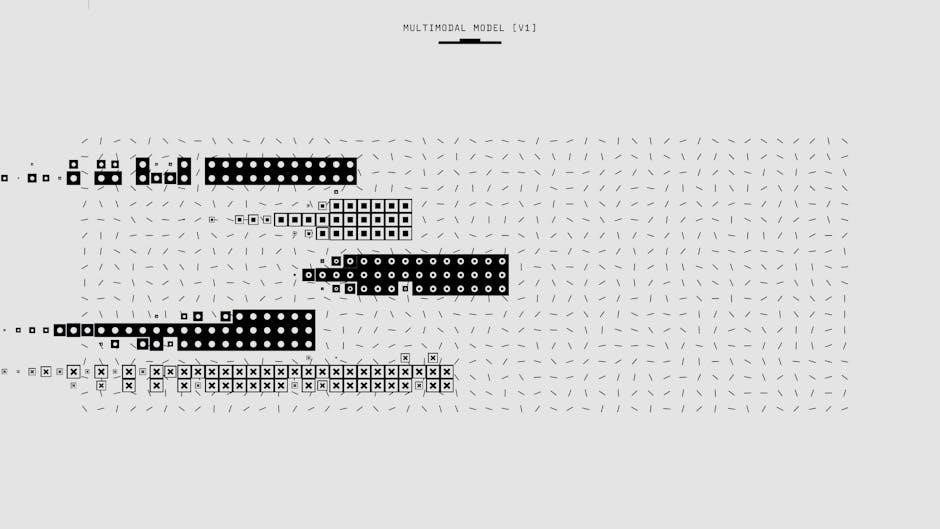

Understanding the Layout of the Starrett Drill Chart

The Starrett Drill Chart is organized into a clear, easy-to-read table format, with columns dedicated to drill sizes, decimal equivalents, and corresponding tap sizes. It includes both inch and metric measurements, ensuring compatibility with various international standards. The chart also features pipe thread sizes, making it a versatile tool for diverse applications.

Each row provides a drill size in fractional or decimal form, its exact decimal equivalent, and the recommended tap size for threading operations. This structured layout allows users to quickly cross-reference measurements, ensuring precision and efficiency in machining and manufacturing processes.

Matching Drill Sizes to Tap Sizes for Precision

Matching drill sizes to tap sizes is critical for achieving precise threading. The Starrett Drill Chart provides a table that lists drill sizes, their decimal equivalents, and corresponding tap sizes for both inch and metric systems. By aligning the correct drill size with the appropriate tap size, users can ensure accurate and consistent results. This prevents common issues like over-tightening or misalignment, which can damage materials or compromise the integrity of the thread. The chart serves as a vital bridge between design specifications and manufacturing execution, ensuring seamless precision in every project.

Applications of the Starrett Drill Chart

The Starrett Drill Chart is widely used in manufacturing, aerospace, automotive industries, and DIY projects. It ensures precision in drilling and tapping, facilitating accurate fastener installation across various materials.

Use in Manufacturing and Production

The Starrett Drill Chart is indispensable in manufacturing and production, ensuring precise drill and tap size selections. It aids in creating accurate holes and threads, critical for component assembly. By providing decimal equivalents and tap sizes, it minimizes errors and ensures compatibility. The chart is widely used in machining processes, helping maintain product quality and consistency. Its availability as a PDF makes it easily accessible for workshop use, supporting efficient production workflows and reducing waste. This tool is essential for maintaining precision and reliability in industrial manufacturing environments.

Applications in Aerospace and Automotive Industries

The Starrett Drill Chart is widely utilized in aerospace and automotive industries for its precision in drill and tap size selection. It ensures compatibility and accuracy in high-precision manufacturing, critical for components like engine parts, gears, and aircraft fittings. The chart’s decimal equivalents and metric/imperial conversions are invaluable for producing threads and holes in materials such as titanium, aluminum, and steel. Its availability as a PDF makes it easily accessible for engineers and technicians, supporting compliance with strict industry standards and minimizing production errors in these demanding fields.

Use by Hobbyists and DIY Enthusiasts

Hobbyists and DIY enthusiasts benefit greatly from the Starrett Drill Chart PDF, as it simplifies projects requiring precise drilling and tapping. The chart provides clear, easy-to-read tables for converting drill sizes to decimal equivalents and selecting appropriate taps. This resource is particularly useful for woodworking, metalworking, and home repairs, ensuring accurate hole sizes and thread pitches. Its availability for free download makes it accessible to individuals without extensive technical backgrounds, helping them achieve professional-quality results in their personal projects and crafts.

Downloading and Printing the Starrett Drill Chart PDF

The Starrett Drill Chart PDF is easily accessible for free download from Starrett’s official website or authorized sources. It can be printed in high quality for workshop use, providing a handy reference for drill and tap sizes in both metric and imperial measurements. This convenience ensures that professionals and enthusiasts can quickly access the chart whenever needed, making it an indispensable tool for precise machining operations.

Where to Find the Official Starrett Drill Chart PDF

The official Starrett Drill Chart PDF can be downloaded directly from Starrett’s website or through authorized distributors. Visit starrett.com and navigate to their resources or literature section, where you can access the chart for free. Additionally, it may be available on trusted tooling websites or forums that host official Starrett publications. Ensure you download from reputable sources to guarantee accuracy and avoid unauthorized versions. This convenient access allows users to obtain the chart quickly and reliably for immediate use in their projects or workshops.

How to Print the Chart for Workshop Use

To print the Starrett Drill Chart for workshop use, download the PDF from Starrett’s official website or authorized sources. Ensure your printer is set to 100% scale to maintain accuracy. Use high-quality paper for clarity, and consider laminating the chart for durability. Print in landscape orientation to fit all data on a single sheet. Open the PDF in a viewer like Adobe Acrobat, select the correct printer settings, and choose standard letter size (8;5×11 inches) for optimal results. This ensures the chart is legible and ready for daily use in machining environments.

Starrett Drill Chart vs. Other Drill Charts

The Starrett Drill Chart stands out for its comprehensive dual-system support, covering both metric and imperial sizes. Its clean layout and precise data make it a preferred choice over others, offering unmatched clarity and versatility for professionals and hobbyists alike.

What Makes the Starrett Chart Unique

The Starrett Drill Chart is renowned for its dual-system compatibility, seamlessly integrating metric and imperial measurements. Its precision and clarity are unmatched, offering a user-friendly layout that simplifies drill size selection. Additionally, it includes decimal equivalents, making conversions effortless. The chart also covers a wide range of drill sizes, from 1-80 to larger diameters, ensuring versatility for various applications. Its comprehensive design and accuracy have established it as an indispensable tool for professionals and hobbyists, setting it apart from other drill charts in the industry.

Comparison with Other Popular Drill Charts

The Starrett Drill Chart stands out for its dual-system compatibility, covering both metric and imperial measurements, while many others focus on one system. Its extensive range, including drill sizes from 1-80 to larger diameters, surpasses the scope of competing charts. Additionally, Starrett’s inclusion of decimal equivalents and clear layout makes it more user-friendly. While other charts may offer similar data, Starrett’s comprehensive design and precision make it a preferred choice for professionals and hobbyists, ensuring accuracy and efficiency in drilling operations across industries.

Tips for Using the Starrett Drill Chart Effectively

Always verify drill sizes with decimal equivalents for accuracy. Use the chart to match drill and tap sizes precisely, ensuring compatibility for your specific project needs.

Best Practices for Selecting Drill and Tap Sizes

Always match drill sizes with corresponding tap sizes using the Starrett chart for precision. Verify decimal equivalents to ensure accuracy in machining operations. Cross-reference thread types and pitch for compatibility. Select taps based on material hardness and desired thread quality. Use the chart to confirm drill sizes for specific thread lengths and diameters. Regularly update your reference materials to align with industry standards; This ensures accurate hole preparation and thread cutting, minimizing errors and improving overall machining efficiency;

Common Mistakes to Avoid When Using the Chart

One of the most common mistakes is mixing metric and imperial measurements; Always ensure the units match your project requirements. Another error is misaligning drill sizes with tap sizes, leading to incorrect thread fits. Failing to account for material hardness can result in tap breakage. Neglecting to verify decimal equivalents can cause size mismatches. Ignoring thread pitch specifications is another frequent oversight. Additionally, using outdated versions of the chart can lead to inaccuracies. Avoid these pitfalls to ensure precise and efficient machining operations.

The Starrett Drill Chart PDF is an indispensable resource for professionals and hobbyists alike, offering precise drill and tap size conversions. Its comprehensive layout ensures accuracy in machining processes, covering both metric and imperial systems. By avoiding common mistakes and following best practices, users can maximize its effectiveness. Available for easy download, the chart remains a vital tool for industries ranging from aerospace to DIY projects, ensuring efficient and precise drilling operations. Its timeless utility and accessibility make it a cornerstone in modern machining.